Averaging Mean Method of PCB Reverse Engineering

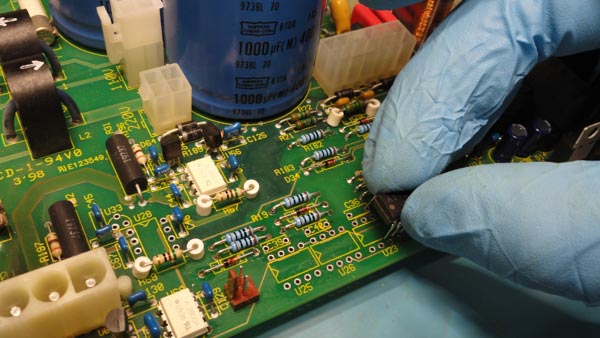

PCB Reverse Engineering Mean method can help to improve the production effeciency and precision by inspecting the layout scheme and schematic diagram extracted from physical printed circuit board;

The averaging mean method of PCB Reverse Engineering is similar to the previous technique except that a measurement of a pre-defined region along the line is used to determine the mean impedance value in that region. This is accomplished by setting the instrument acquisition in averaging mode (n>8). Documenting the correct scaling (vert./horiz.), test structure, and pre-defined mean region will provide the best means for correlation between different equipments and users for PCB Reverse Engineering test methodology.

The averaging mean method eliminates error due to user dependency and response ringing. This is particularly important for instances where excessive ringing occurs on the TDR response and the difference between peaks and valleys are a large percentage of the specification window after PCB Reverse Engineering. Taking the mean and selecting the proper region in which to take measurements minimizes a large portion of these errors.

The response in Figure 16 illustrates an averaged pulse response and a good general measurement region that is used to determine the impedance for a 28Ω measurement through PCB Reverse Engineering impedance test.

Current IPC spec is to measure between 25–85 % of response. This is based on previous common 50–70 Ω measurements. Low impedance measurements such as Direct Rambus 28 Ω need to follow the illustration below to yield accurate results.

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering