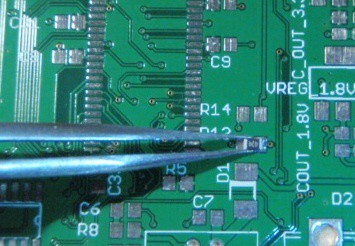

PCB Plate Reverse Engineering Inspection

PCB Plate Reverse Engineering Inspection can ensure the 100% correctiveness of the recovered PCB board layout, routing file, gerber and schematic;

PCB hardware analysis before reverse engineering process can be determined by a series of effects. One of the most important factors is mechanical design element, as we all known, mechanical design can greatly affect the whole reliability and consistency with other parts. It will determine if the whole PCB Eeverse Engineering process can be proceed smoothly.

As we all know, the PCB plate can provide the mechanical support for the whole system and for all the components, however, it can’t be used as structure part to support and undertake the whole weight of device. As a result of that, in the edge of PCB plate, there must be physical support for each five inches.

There are several items need to be taken into consideration:

1. structure of pcb plate, such as size and shape;

2. the type of socket and required mechanic accessory;

3. the adjustment and compatibility for environment terms of circuit;

4. other items such as heating and ash to assemble pcb plate vertically or horizontally;

5. some items need to emphasized on include: thermal dissipation, ventilation, shock, vibration, ash, salt dust or radiation;

6. the level of mechanical support;

7. hold still and fix, easy to fetch;

Tags: repetir placa de circuito impresso bom,repetir placa de circuito impresso design,repetir placa de circuito impresso diagram,repetir placa de circuito impresso gerber,repetir placa de circuito impresso layout,repetir placa de circuito impresso schematic