Printed Circuit Board Re-development

Points to note in the process of Printed Circuit Board Re-development refers to handling, storage and cleaning before re-manufacturing;

Avoid exposing copper traces to the air,

If the copper traces of the circuit board are exposed to the air, especially when there is a long time interval between manufacturing and assembly, they may be oxidized and contaminated.

The best way to avoid this situation is to make the surface as smooth as possible during the printed wiring board manufacturing process.

Avoid debris residue

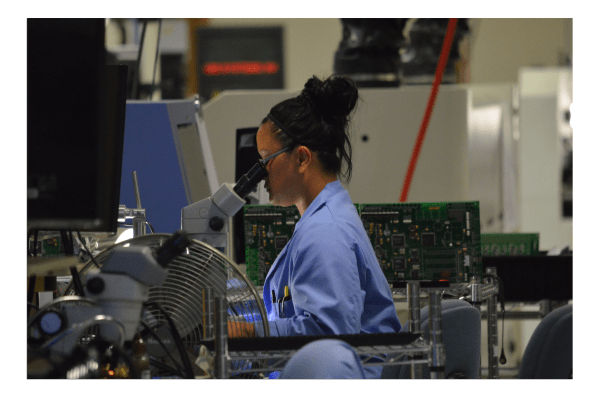

During PCB assembly (PCBA), debris may accumulate on the PC board surface. Since the debris is small, it may be difficult to find. Therefore, it is best to use optical inspection and clean the circuit board after assembly.

Avoid excessive pressure

When manually handling the circuit board, it is necessary to avoid applying excessive pressure to the circuit board. Excessive pressure may cause the circuit board to deform or break, thereby affecting the integrity of the circuit board structure.

Wear protection

Contaminants may also be deposited when the plates are manually processed. This includes dust, sweat, etc. Therefore, you should wear gloves when handling.