PCB Reverse Engineering Assembly Quality

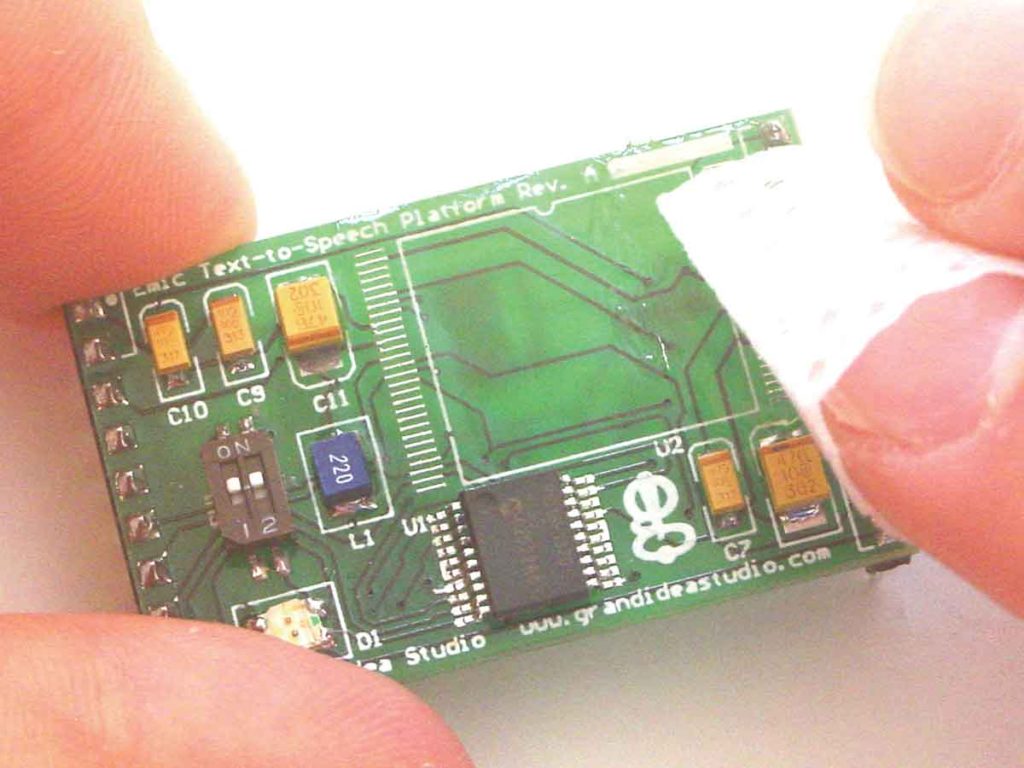

PCB Reverse Engineering Assembly Quality depends on the rationality of PCB board components arrangement and layout position, which can be modified through PCB board reverse engineering process;

Printed Circuit Board Assembly Defects base upon the assembly file and orientation file from Gerber file by Reverse Engineering printed circuit board can be caused by several reasons, hereby we would like to introduce several reasons which affect the stability of assembly printed circuit board:

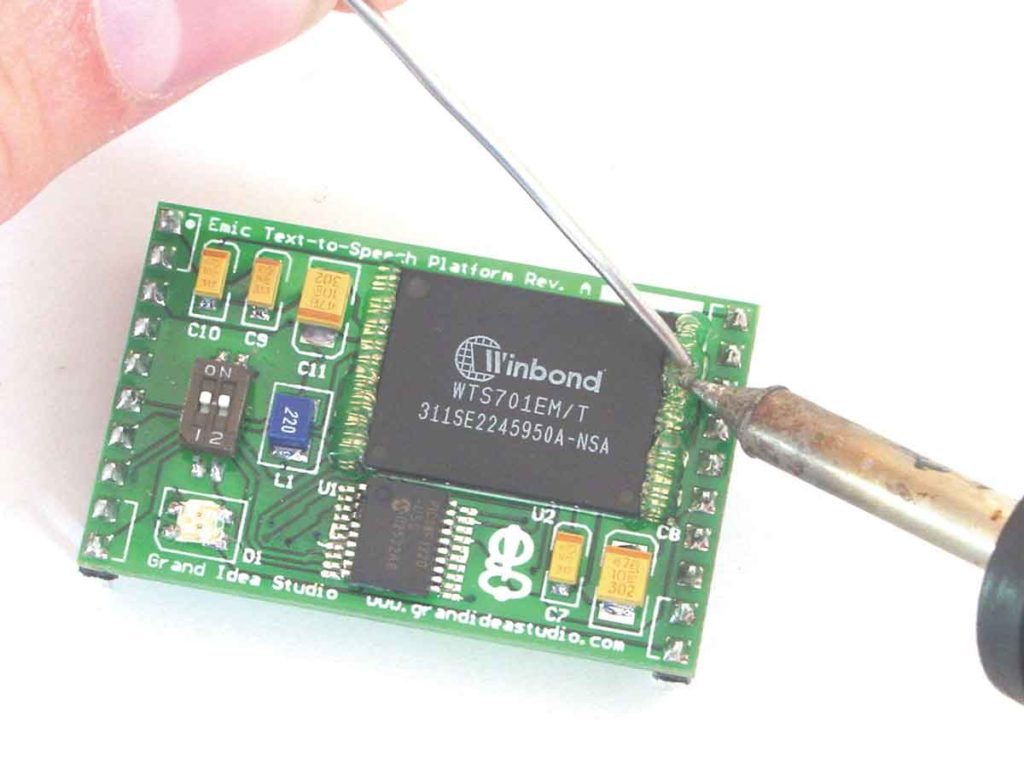

The solderability of printed circuit board hole will affect the assembly quality, if the holes don’t have a good solderability, cold soldering will occur and affect the component parameter in the printed circuit board, especially for multilayer printed circuit board will cause component and internal layer unreliability which will ultimately cause the malfunctioning of whole system.

Solderability of printed circuit board means the features of metallic surface after the solder tin melted down, and form a relative even, constant and smooth adhesive thin film on the surface before assembly printed circuit board. There are several items will affect the solderability of printed circuit board assembly which can be improved and solved properly by improve PCB design through Reverse Engineering technique:

1 component of solder tine and features of printed circuit board pad; solder tin is the most important ingredient of chemical processing when assembly printed circuit board, which was constituted by chemical ingredient containing flux. The most usual low melt down metal is SN-PB or SN-PB-AG.

2 soldering temperature and metal plate surface cleanness will also affect the printed circuit board assembly. If overheated, then the solder tin spreading speed will be faster and higher flexibility, which will cause the printed circuit board and solder tin surface oxidated immediately and bring the defect of printed circuit board assembly. If the surface of printed circuit board being contaminated will also caused the inferior assembly quality include solder tin ball and drop, open circuit and etc.

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering