DC TO DC CONVERTER PCB Board Duplication

In many industries—ranging from telecommunications and automotive to aerospace and industrial automation—DC to DC converters are essential components that regulate voltage and ensure stable power delivery. These power modules often come embedded in custom or proprietary equipment. However, as technology advances or manufacturers phase out older models, companies are often left without access to the original Gerber files, schematic diagrams, or layout drawings needed to repair, replace, or reproduce these vital boards.

This is where our DC TO DC CONVERTER PCB board duplication service steps in. By leveraging advanced reverse engineering techniques and years of industry expertise, we help companies and individuals recover, restore, and recreate legacy circuit boards that are no longer in production—but still crucial to ongoing operations.

A sample Cost-Estimating Guide after PCB Duplicate is base upon several important factors include complexity level of pcb manufacture procedure, because the higher layer count, the more will be costed to manufacture it;

second point refers to the part list, the more obscure and/or advanced of these parts, the higher cost it will take, during process MOQ (minimum order quantity) could be another headache problem for project leader since some parts you have to order hundreds or even thousands but you need maybe only several piece of them.

The Value of Duplicating a DC to DC Converter Board

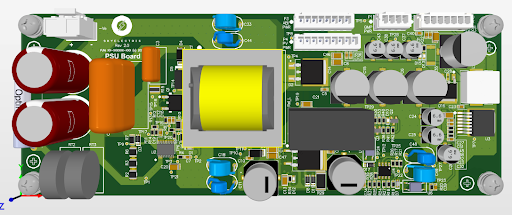

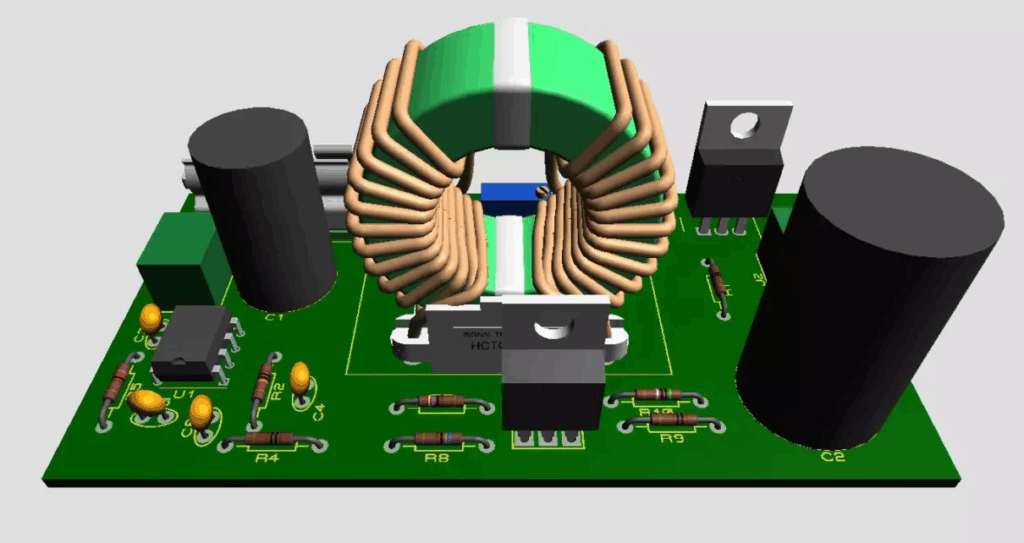

DC to DC converter PCBs are often designed with specialized topologies such as buck, boost, or buck-boost circuits. They involve precise component selection, heat dissipation strategies, and tightly packed high-frequency layouts. Losing the documentation for such a board can render entire systems inoperable or impossible to maintain. Through DC TO DC CONVERTER PCB board duplication, we clone or copy the existing hardware to produce complete engineering files that match the original design exactly, or can be redesigned for improved performance or newer components.

Our process results in the delivery of:

- Fully verified schematic diagrams

- Ready-to-fabricate Gerber files

- Detailed layout drawings

- Accurate BOM list (Bill of Materials) with footprint and specification details

- Comprehensive netlist for signal and power integrity validation

These outputs allow customers to remanufacture new boards, redeploy them in field equipment, or use them as a baseline for redevelopment.

PCB reverse engineering could become the less expensive process at this moment and finally, the most expensive and important part of produce a sample through data obtain from PCB duplication is PCBA functionality test according to customer provided documents, requirement or any instruction book. etc.

These are only guidelines and most data was derived during the trial program; however, the estimates for drawing preparation, producibility studies and quality control reviews are based on years of experience.

Applications and Use Cases

Whether you’re a system integrator, maintenance team, or OEM supplier, the ability to duplicate a DC to DC converter PCB board offers critical advantages:

- Extend equipment life: No need to redesign from scratch or buy expensive replacements.

- Support legacy systems: Keep mature products operational with readily available replacements.

- Enable refurbishment projects: Refurbish used equipment and restore it to full functionality.

- Facilitate product improvement: Use reverse-engineered data to redesign for better efficiency or thermal management.

A Proven Reverse Engineering Workflow

Our duplication process begins with the physical examination of the donor PCB. From there, we perform high-resolution scanning, track tracing, and layer reconstruction. Each component is identified and mapped into the BOM list. Then, our engineers build the schematic diagram and layout drawing, cross-validated against the netlist and original circuit behavior.

Once the files are completed, we offer prototype fabrication, testing, and verification, ensuring your duplicated DC to DC converter performs identically to the original.

For companies and individuals faced with aging equipment, DC TO DC CONVERTER PCB board duplication offers a cost-effective, technically sound solution to maintain, repair, or even improve existing systems. With complete data restoration—Gerber files, BOM lists, schematics, and more—you’re empowered to take control of your hardware’s lifecycle and avoid unnecessary downtime or cost. Let us help you recover and reproduce what time and obsolescence have taken away.

Tags: duplicate circuit board,duplicate pcb card,duplicate printed circuit board,duplicate printed wiring board,duplicate pwb