PCB Clones Value

In today’s fast-paced technological environment, products and equipment evolve rapidly. Unfortunately, this constant evolution also means that many critical components, including circuit boards, become obsolete over time. For businesses and individuals alike, the ability to recover, restore, and recreate these vital electronics is essential. This is where the PCB Clones Value truly shines — offering a powerful way to reproduce and remanufacture existing PCBs when original resources are no longer available.

Unlocking Lost Designs Through PCB Cloning

PCB cloning is a sophisticated reverse engineering process that allows engineers to duplicate an existing printed circuit board (PCB) without access to original design documents. By analyzing the physical board, skilled engineers can restore critical technical data, such as Gerber files, schematic diagrams, layout drawings, BOM lists, and netlists.

Through advanced scanning, measurement, and diagnostic techniques, even heavily customized or aging PCBs can be copied and redeveloped to serve current operational needs. The PCB Clones Value lies not just in replication, but in giving businesses an efficient pathway to maintain, refurbish, and even upgrade systems without major redesign efforts from scratch.

Key Benefits for Companies and Individuals

- Cost Efficiency

Cloning and refurbishing an existing PCB saves significant time and resources compared to designing a new board from zero. Especially for industries relying on legacy systems, redevelopment through PCB cloning is far more affordable and practical. - Business Continuity

When manufacturers phase out older equipment, spare parts, including specific PCBs, can become impossible to source. Reproducing and remanufacturing these critical boards ensures that operational downtime is minimized, protecting production lines, defense systems, medical devices, and more. - Intellectual Asset Preservation

The ability to recover a schematic diagram or layout drawing from an obsolete PCB means valuable intellectual property isn’t lost. Businesses can restore original documentation and preserve it for future upgrades or compliance audits. - Upgrade and Redesign Opportunities

Once a board is successfully replicated, companies can easily redesign or enhance its functionality. Perhaps new materials, updated components, or modern design rules can be applied to boost performance while retaining the original system’s compatibility. - Support for Research and Development (R&D)

For individuals and institutions engaged in R&D, copying a PCB provides a strong baseline for further innovation. Engineers can recreate and tweak existing designs, accelerating the prototyping process for new technologies.

The Technical Process of PCB Cloning

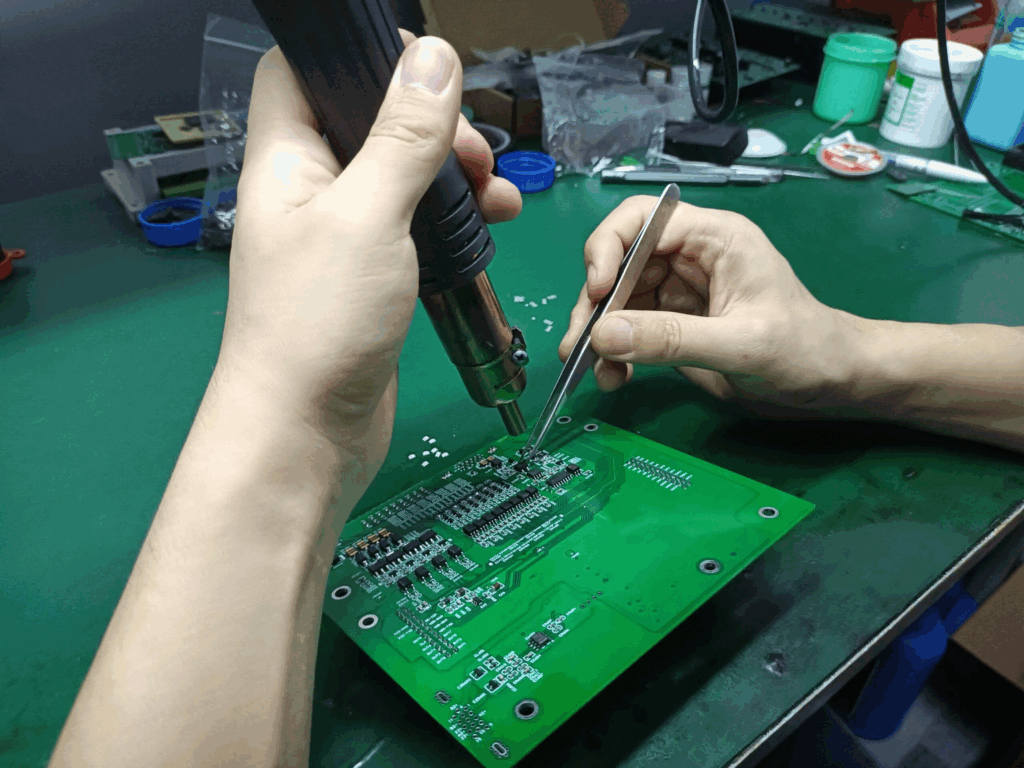

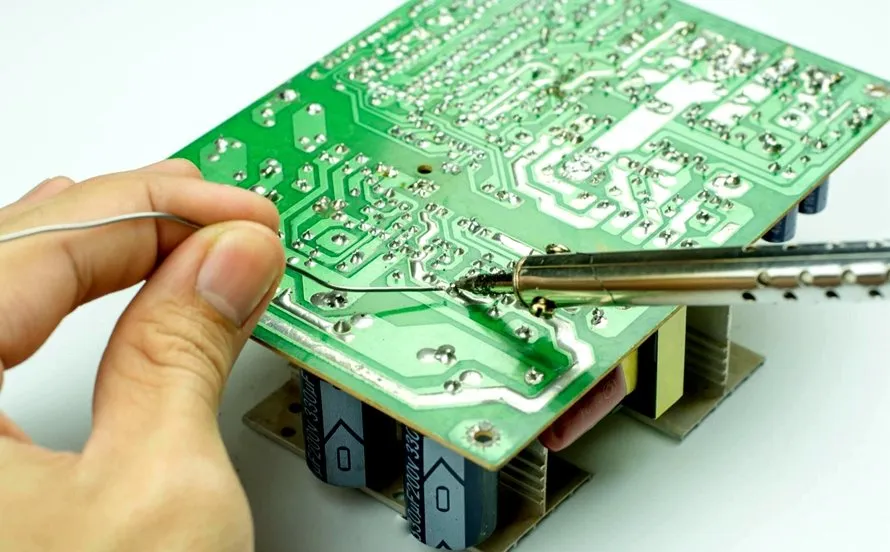

The journey to unlock PCB Clones Value begins with a detailed examination of the existing physical board. Engineers carefully desolder components if needed and scan all layers to accurately recover track patterns and via structures.

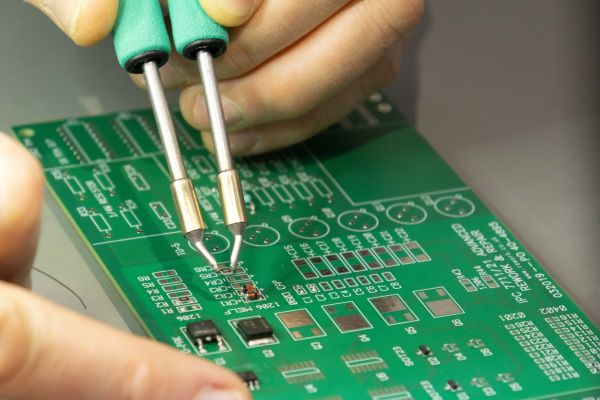

Next, a precise Gerber file, BOM list, and netlist are reconstructed using specialized software. A detailed schematic diagram and layout drawing are then recreated and verified through electrical testing.

Finally, a prototype PCB is manufactured and assembled to ensure that the cloned board matches the functionality and performance of the original. This process ensures that even the most complex and densely routed PCBs can be duplicated and validated for practical use.

PCB Clones value has been proved over the last decade of development of this technology, some people has ever hold this kind of illusion: if research and develop a consummer product need to spend 2 years, then after this process has been done by other great weight competitor, the small and medium size company who intend to produce this consumer product will need to spend extra 2 years to do the research and development, during these 2 years they can only sell other competitor’s products, which means their product could be 4 years later than their competitors whose brand and market share has been established and extended in the relatively less competitive market.

However, if the application of reverse engineering technology such as pcb clone or ic crack, when the launch of this new product, we can promptly keep pace with the new PCB research and integrate new functions and features to these products. Through this our market share and product brand can be set up sooner and have chance to compete with other producers.

Nowadays, PCB clone service technology has been extended to different sectors which include medical device, communication terminal, electronics, industrial control, meter, broadcast, automobile, home appliance as well as security product.

Tags: double sided pcb clone,multilayer pcb clone,single side pcb clone