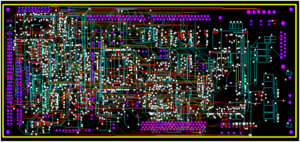

PCB Board Reverse Engineering Inspection

PCB Board Reverse Engineering Inspection means the circuit board documents extracted from physical sample must be checked to ensure the accuracy of the PCB file cloning.

PCB Board reverse engineering need to check the circuit pattern quality, electrical connection and track route stability and rationality. The items need to be checking include:

1 tracks can be short and straight without the sacrifice of functions when reverse engineering pcb board;

2 if the reverse engineering has followed the limitation rules for track width;

3 among the tracks, tracks and fixed holes, tracks and soldering pads, if sufficient space has been saved for them;

4 if all the tracks have already avoided the parallel tracks (include the component leads);

5 if the sharp angle has been avoid;

6 check if the schematic diagram is rational and correct;

7 check if all the component packages are all correct and rational;

8 strong and weak electricity distance and the space between blocked areas;

9 check the schematic and PCB drawing correspondingly to avoid the lost of netlist provided by pcb board reverse engineering;

10 if the footprint of component can match with physical sample;

11 if the placement of components when reverse engineering pcb board are all properly;

Tags: klon pwb bom,klon pwb design,klon pwb diagram,klon pwb gerber,klon pwb layout,klon pwb part list,klon pwb schematic,replicate circuit board,replicate circuit card,replicate pcb,replicate pcb assemble,replicate pcb board,replicate pcb card,replicate pcba,replicate printed circuit board,replicate printed wiring board,replicate pwb