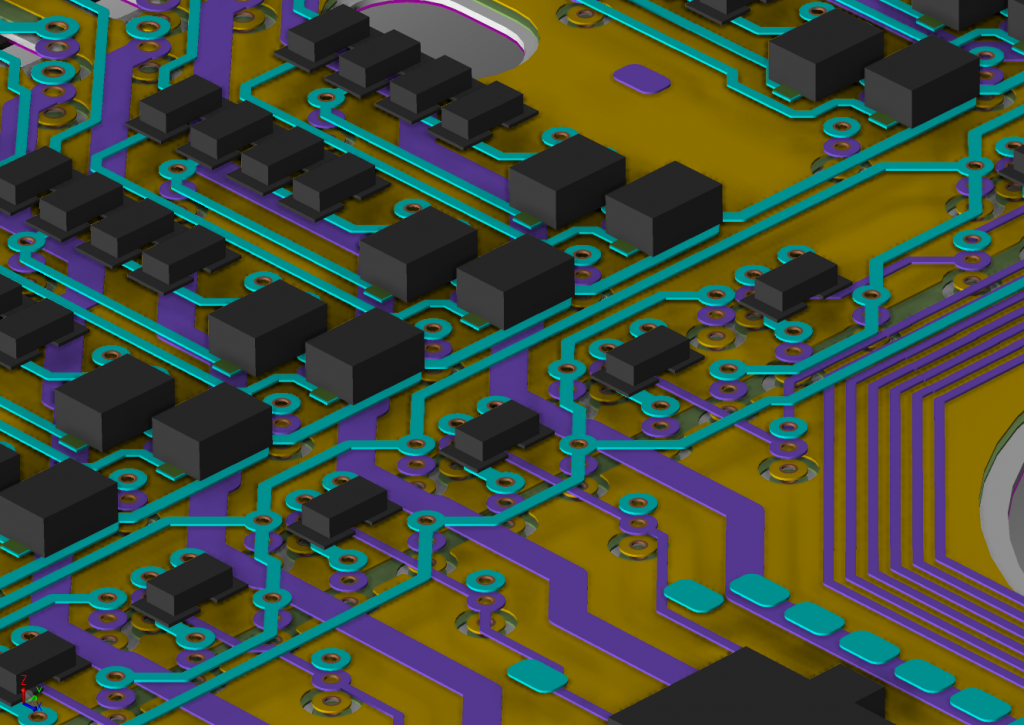

Electronic Circuit Card Cloning

In this kind of system design from Electronic circuit card Cloning, careful planning of power supply system design and choose the most reasonable power supply system’s decoupling strategy, and these two items can be combined tightly to ensure the stability of the power supply system.

And swift signal is much easier to generate the radiation in the process of Electronic PCB card Cloning, as a result of that, EMI is becoming more and more concerned by the design engineers, which also become one of the most important aspects in the PCB Card cloning procedures. Especially in today’s electronic product must confront and deal with a lot of standards;

Unfortunately, in the relative low speed design system, shorten signal rising time length will cause the potential risk which will frequently be omitted by the engineers in the process of Electronic PCB card cloning signal integrity. That is because most of the engineers not quite willing to execute the signal integrity analysis and spare no effort to avoid it which will turn out to be the real danger since a great amount of printed circuit boards will be sent to manufacturers for production before the signal integrity issue has been clarified. At the same time, due to the signal integrity issue itself is unpredictable, signal integrity issue is not able or applicable to present even after the Electronic circuit cards have been made and proceed the functionality test after high speed pcb board Cloning, only after the arrival of final product in the hand of end users, the signal integrity issue will come into being.

In the process of PCB card Cloning, the product failure on the end user scene will turn the diagnosis and solution of the issue become extremely difficult to tackle. And the true risk is obviously higher than the NON-RECURRENCE ENGINEERING COST. And each one of the Electronic circuit card manufacturers will attribute these NRE cost into the life cycle of products. After the Electronic circuit card has been reverse engineered, due to the unpredictable high speed signal integrity issue can cause the repetitive design which directly lead to the NRE cost rising up to an unacceptable level.

Tags: copy 2 layer pcb bill of material,copy 2 layer pcb bom,copy 2 layer pcb design,copy 2 layer pcb gerber,copy 2 layer pcb layout,copy 2 layer pcb schematic