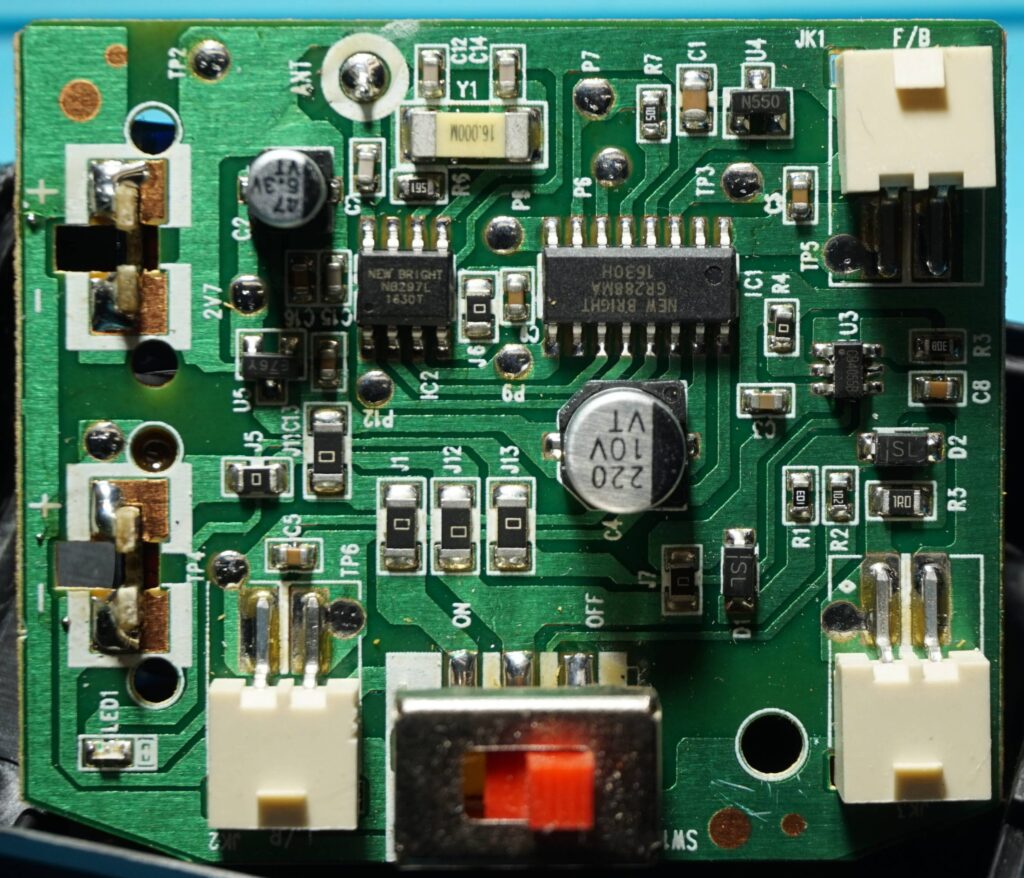

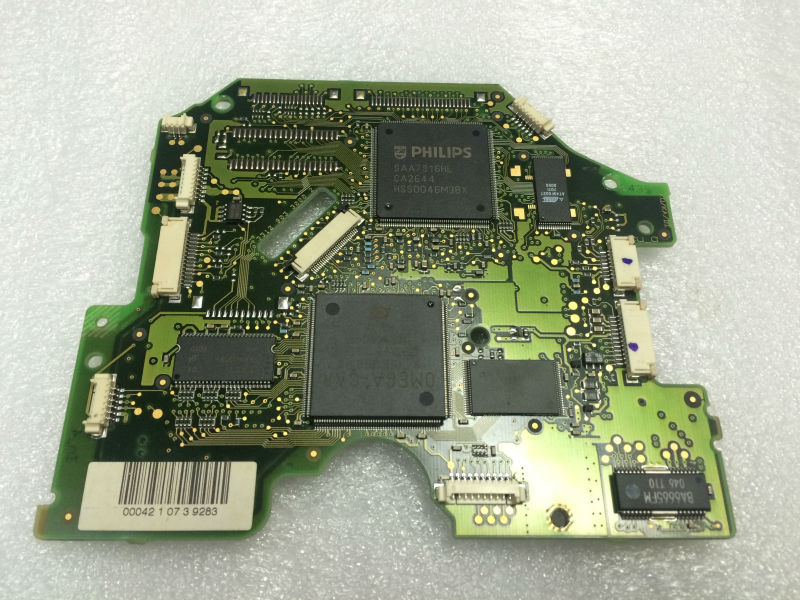

Automobile Electronic Circuit Board Reverse Engineering Simulation

Automobile Electronic Circuit Board Reverse Engineering Simulation, or virtual pcb board prototyping simulation, has become an increasingly important step in the automotive electronic pcb board reverse engineering process. As mentioned earlier, simulation not only saves time and expense in the development process, but also simulates longer-term abuse effects in the harsh environment of the car.

Like Mention Electronics’ ExpediTIon Enterprise, a complex PCB system design solution includes multiple forms of virtual prototyping capabilities, including:

Analog and Digital Signal Integrity Analysis,

power integrity

Oscillation and Vibration

Manufacturing Design

A convention that takes advantage of all these features is that a good designer will use all features throughout the design process, rather than waiting until the end.

Combining these simulation results to redesign until the end of the process wastes time and effort and is prone to compromise. Incorporating good virtual prototyping into the design process can lead to overdesign (i.e., a very conservative design approach), but often this results in increased product cost and loss of performance without guaranteeing continued reliability. Let’s look at three examples of good virtual prototyping practices during product development.

Tags: copie la placa de circuito electrónico del automóvil,placa de circuito electrónico del automóvil clon,replicar la placa de circuito electrónico del automóvil,tablero de circuito electrónico de automóvil duplicado