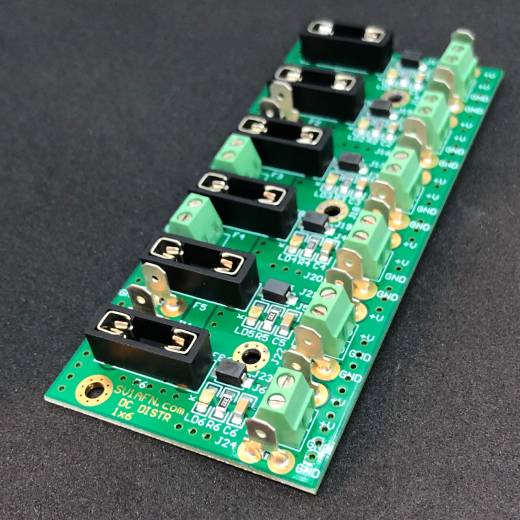

Replicate a Power Distribution Module PCB

The power distribution module circuit board is unlike generic PCBs. It often integrates high-current paths, protective circuitry, switching devices, and communication interfaces. Because of this complexity, replicating power distribution module circuit boards requires more than just copying traces—it demands precise engineering analysis and a deep understanding of electronic design.

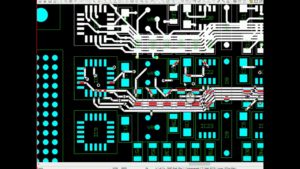

Our process begins with a physical evaluation of the board. Using advanced imaging and diagnostic tools, we identify all relevant details: the layer count, track width, via design, and component placement. From there, we generate all necessary technical documentation, including:

- Gerber files for PCB fabrication

- Schematic diagrams showing component interconnection

- Layout drawings for visual and production references

- A detailed BOM list (Bill of Materials)

- An accurate netlist for electrical validation

These outputs are essential for remanufacturing, redesigning, or recreating the PCB for future applications. If desired, we can also support redevelopment, where the original design is modified for enhanced performance, regulatory compliance, or component substitution.

PCB Replicate need to experience the phase of data collecton, the purpose of the Data Collection is to secure all the unrestricted documentation available, to preclude unnecessary duplication and to facilitate the development of technical documentation through pcb duplication process. The following data is desirable:

a. Next higher assembly, which provides information on input/output parameters, mating parts, end-use, etc;

b. Specifications, such as part specification include PCB, resistor, capacitor and different kinds of integrated circuit; Test Specifications include the pcb bare board inspection, in-circuit testing after pcb assembly; Acceptance Test Procedures, Purchase Descriptions, etc;

c. Parts list/data list, which identifies all parts and indicates if they are standard National Stock Numbers (NSNs), Military Standard (MIL-STD) parts, etc. The Data List should indicate the applicable drawings and specifications necessary and provide valuable information on specifications that should be researched to remove restrictive requirements; At the same time, part list should include all the information about phase out or upgraded parts;

d. Schematic diagram obtain from PCB copying service or PCB Layout, which provide basic information for the Physical Configuration Audit (PCA), verify the parts list, and save time in tracing circuitry (i.e., Printed Circuit Board (PCB) wiring diagram);

e. Next lower assembly, which identifies interfaces, input/output parameters, mating parts, etc.

The value of replicating power distribution module circuit boards extends far beyond cost savings. For many industries, time is critical. Waiting for new parts or redesigning systems from scratch can lead to delays, downtime, and increased operational costs. Our PCB cloning services allow you to duplicate and remanufacture needed boards quickly and with high accuracy.

We help clients avoid vendor lock-in, manage supply chain risks, and continue using tried-and-tested designs with full confidence. Our services are especially useful when legacy equipment must remain operational, but technical files have been lost or destroyed. By restoring obsolete PCB documentation, we offer our clients the ability to recreate their hardware platform from the ground up.

Whether you’re maintaining a fleet of aging machinery or building custom control systems, replicating power distribution module circuit boards is a smart, strategic solution. Through a combination of reverse engineering, redesign, and document recreation, we help organizations safeguard their investments and preserve critical infrastructure. Let us help you bring your legacy systems back to life—with precision, reliability, and innovation.

Tags: replicate circuit board,replicate pcb board,replicate pcb card,replicate printed wiring board,replicate pwb