Printed Wiring Board Reverse Engineering Manufacturing

Second step need to take the printed wiring board reverse engineering rule and limitation into consideration, if the PCB board reverse engineering task can be done smoothly, tools must work in the environment of correct rules and proper limitation. All the signals track with special requirement must be classified, all sorts of signals must have priority level, the higher the priority level, the strict the rule is it. These rules should include Printed Wiring Board track width, through hole maximum quantity, parallel level and interference among these signal tracks and layer count limitation. These rules will play an extremely influence on the PCB reverse engineering tools and process.

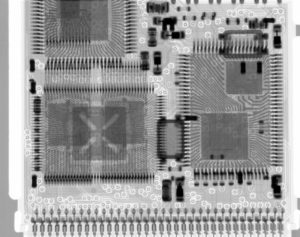

Component Layout

In the pursuit of component assemble optimum, reverse engineering for manufacturing rule will have restriction on the component layout. if the printed circuit board assemble department allow to move the component location, the process can be optimized advisablely and will make it more convenient for automatic processing and layout. Automatically PCB reverse engineering will only take one signal into consideration, PCB Reverse Engineering tools can complete the layout work like the engineers through the installation of reverse engineering limitation rules and signal layer for reverse engineering and layout.

Tags: pcb assemble duplicate,pcb board duplicate,pcb card duplicate,pcb duplicate,pcba duplicate,printed circuit board duplicate,printed wiring board duplicate,pwb duplicate,pwba duplicate