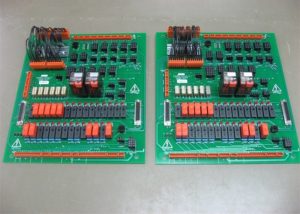

PCB Board Clone

In order to minimize the impact on the PCB Board Clone, ADC time clock source must have very low time setting oscillation or phase noise. If the sectors won’t be taken into account when choosing time clock circuits, then systematic motivated features won’t be excellent. And it is not related to the fixed oscillation features in the frontend analog input circuit’s quality or transformer. Precise time clock can always provide the edge switch in the accurate time separation.

As a matter of fact, time clock can achieve within the same continually changing time cycle. As a result of that, the uncertainty of the time setting can evaluate the wave shape signal noise ratio comprehensively through using data changing process;

The maximum time clock vibration is formulated by beneath terms:

Tj(rms)=(VIN(p-p) /VINFSR)×(1/(2(N+1)×π×fin)

Presumed input voltage (VIN) is equal to ADC standard scope (VINFSR), then the vibration request can change ADC resolution (N bits) and applied input frequency (fin) element, as for 70 Mhz input frequency, the total vibration request is Tj(rms)=1× (1/215π×70×106)) Tj(rms)=140fs;

Since most of the systems can distribute the reference clock through backplane or other connection from the old library acquired by PCB circuit board reverse engineering, and it will deteriorate the signal quality, as a result of that, normally use the machine oscillactor as the ADC timer source. Use LMX2531 time clock to constitute generation made by NS company.

Circuit Engineering Co.,Ltd. is a small business located in shenzhen, China in a 10,000 square foot manufacturing facility. We are dedicated to customer service and offer comprehensive PCB card Clone services tailored to meet our customers’ needs. Our staff is friendly and courteous and stands ready to assist you by providing superior PCB reverse engineering Services at competitive prices.

Circuit Engineering Co.,Ltd. provides services for all of your PCB Board Clone requirements. Working from your specifications or documentation, we assist with projects and products from design, prototype, to full scale manufacturing on either a consigned or turnkey basis. Our employees have a strong customer focus ensuring the attention needed to handle your outsourcing needs. The mechanical and electronic design groups help with your product design or modification needs. We work closely with your staff, enabling an effective and timely response. Our flexible facility provides for simultaneous outputs for many products in a time frame that meets your requirements.

Full service PCB Board Clone service provider of medical, commercial and industrial electronics

In house design and development engineering

Low to mid volume manufacturing GMP Certified

ISO 13485 compliant

Follow IPC A 610 Standards

Tags: replicating pcb board artwork,replicating pcb board bom,replicating pcb board cad file,replicating pcb board component list,replicating pcb board design,replicating pcb board diagram,replicating pcb board drawing,replicating pcb board gerber file,replicating pcb board layout,replicating pcb board part list,replicating pcb board schematic