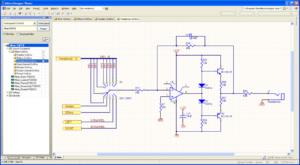

Reverse Engineering Circuit Board Quality Control

Quality control (QC) of PCB Reverse Engineering introduction:

1st point is Quality control study of circuit board reverse engineering, A quality control study should be performed and documented on the Level 3 drawings and prototype of candidates to certify their compliance with original candidate specifications.

2nd step is Quality control plan of circuit board reverse engineering: A quality control plan should be developed to ensure the product conforms to drawings, specifications, inspections, tests, and task order requirements.

3rd point is Quality control inspections of circuit board reverse engineering: Quality control inspections should be applied to the procurement of supplies and services, as follows:

a. Engineering service contracts where software/documentation deliverables are necessary, and

b. Minor limited production or prototype hardware contracts where inspection is the major quality control factor.

4th step is Quality control program of circuit board reverse engineering. A quality control program that applies to complex supplies, components, equipment, and systems should be implemented to provide the necessary quality assurance.

Circuit Engineering Company Limited provide a complete PCB Reverse Engineering, PCB Clone and PCB Restoration service, Rapid Prototyping and functional test services using the latest technologies combined with traditional skills for a wide range of industries. By integrating our traditional skills with the latest technologies, we can offer clients a comprehensive portfolio of product development services all under one roof. For more details please contact our customer

service team.

Tags: double side circuit board reverse engineering,flexible circuit board reverse engineering,multilayer circuit board reverse engineering,powielać płytki drukowanej artwork,powielać płytki drukowanej bom,powielać płytki drukowanej component list,powielać płytki drukowanej design,powielać płytki drukowanej gerber file,powielać płytki drukowanej layout,powielać płytki drukowanej schematic,rigid flex circuit board reverse engineering,single side circuit board reverse engineering