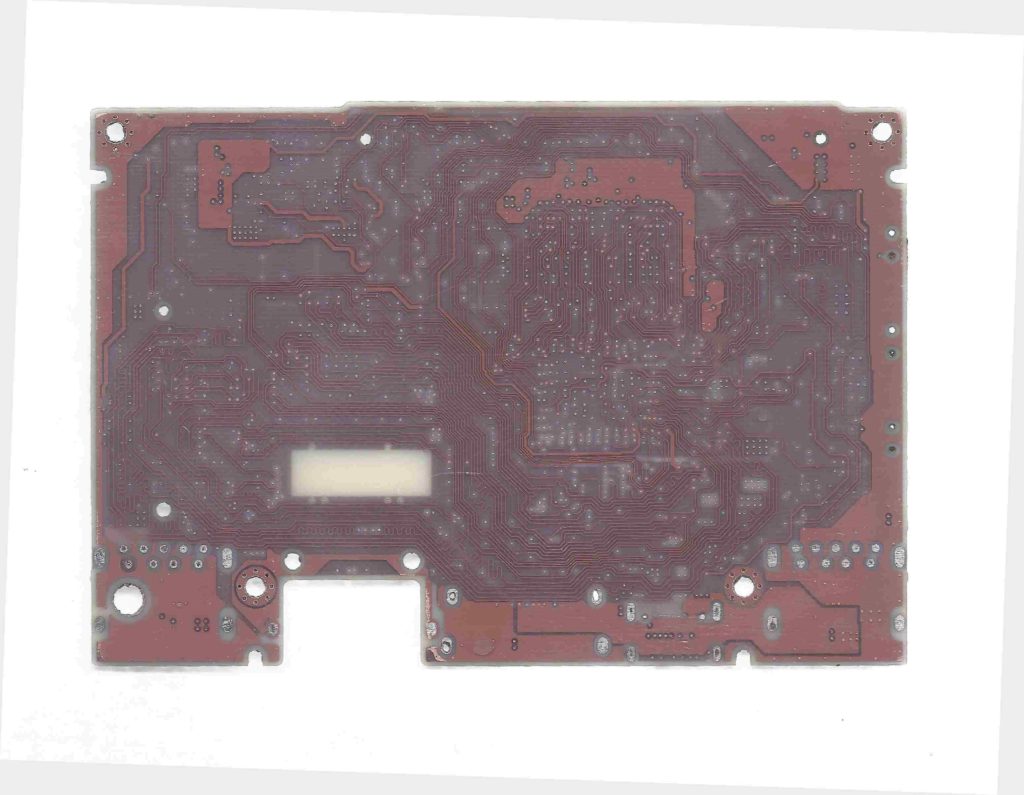

Printed Circuit Card Reverse Engineering

Printed Circuit Card Reverse Engineering is a process which can restore the PCB board layout drawing and schematic diagram out, and these documents will be used for reproduce PCB board;

In the process of Printed circuit card Reverse engineering, The generate object report entry from the Info menu provides a way to get detailed information about an object, such as its coordinates, dimensions, etc.

You can also get a report summarizing all of the drills used on the board from electronic pcb card Reverse engineering with ‘generate drill summary’. Lastly, you can get a list of all pins, pads and vias that were found during a connection search.

The Window menu provides a way to bring each of PCB Reverse engineering’s windows to the front. The Library window is used to bring elements from the library into the paste-buffer. The Message Log window holds the various messages that sends to the user.

The Netlist window shows the list of connections desired. Now that you’re familiar with the various menus, it’s time to try some things out. From the File menu choose ‘load layout’, navigate to the tutorial folder, then load the file ‘tut1.pcb’.

Circuit Engineering Co.,Ltd. is dedicated to delivering the highest quality Printed wiring board Reverse engineering services with an approach that is tailored to meet the needs of medium sized OEMs. We specialize in turnkey manufacturing of high mix, high complexity products for military, avionics, industrial, medical, and energy management markets. Circuit Engineering Co.,Ltd.’s history of building strong partnerships and developing flexible solutions differentiates us from the rest of the EMS industry.

Our passionate people and efficient processes support aggressive new product introduction timelines, and a smooth transition of those products into production. Employees are empowered to deliver superior program management, supply chain management, exceptional workmanship quality, efficient test strategies, and final assembly and packaging solutions that ensure the successful PCB card cloning and manufacturing and on-time delivery of your products.

Tags: cloning printed circuit card artwork,cloning printed circuit card bom,cloning printed circuit card component list,cloning printed circuit card design,cloning printed circuit card diagram,cloning printed circuit card drawing,cloning printed circuit card gerber file,cloning printed circuit card layout,cloning printed circuit card part list,cloning printed circuit card schematic