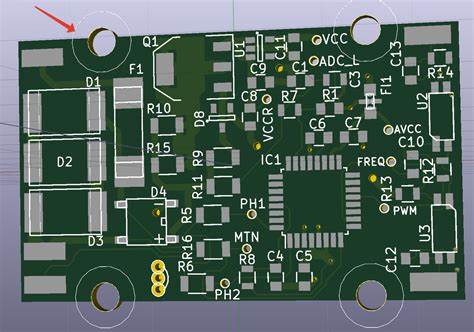

PCB Plate Reverse Engineering

Mechanical design is an important step after PCB Plate reverse engineering, next one we need to talk about the Installation of electro-mechanical assembly, the mechanical support should be exist in three rims of PCB plate within one inch of its edge, according to the practical experience, if the thickness of pcb plate is around 0.031 to 0.062 inch, then the distance of its support location should be at least 4 inches; if the thickness of pcb plate is greater than 0.093 inches, then the distance of each support pins should be at least five inches according to PCB board design checking rule.

This principle can effectively improve the pcb plate rigid capability and eliminate the syntony. And the pcb board reverse engineering dimension analysis can only be determined after below items being confirmed:

1. the area on the pcb plate where doesn’t need to mount the components;

2. effect of insert and withdraw tools on the distance between two pcb plate installation;

3. redesign fixed hole and slot in the pcb plate from reverse engineered layout;

4. insert and withdraw tools must be placed in the device for usage, and their measurement must be taken into account;

5. need to use a insert and withdraw device, and normally will use screw to fix it onto the pcb plate eternally;

6. in the fixed body frame of pcb plate, and need the special design and reverse engineering on the pcb plate load bearing flange;

7. the adaptability of insert/withdraw tools with PCB plate dimension, shape and thickness;

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering,reproduire pcb bom,reproduire pcb gerber,reproduire pcb part list,reproduire pcb schematic