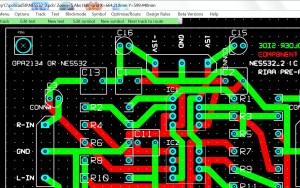

PCB Reverse Engineering Hardware Analysis

PCB Reverse Engineering Hardware Analysis is one of the most important steps for completion of this work. PCB Reverse Engineering Hardware Analysis can made things better clear. A hardware analysis should be performed during the stage of PCB reverse engineering preparation to develop the missing data required for a technical data package.

In those cases where the existing technical documentation is either incomplete or unavailable, hardware analyses (dimensional, material, electrical/electronic) should be performed to develop the technical data (product baseline) required for production. The data developed by physically examining, measuring and analyzing the existing hardware should be included in the end-item drawings and specifications.

Accuracy is the pretext and foundamental point for hardware analysis. All test equipment should be calibrated prior to use in order to detect and adjust any variation in the accuracy of the instrument being checked from PCB Reverse Engineering Hardware Analysis. ISO 10012-1 and NCSL-Z540.1 may be used as guidance for the calibration of all measuring and test equipment.