Annular Ground Design In Circuit Board Reverse Engineering

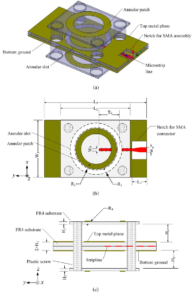

Annular Ground Design In Circuit Board Reverse Engineering is placed around the circuit in the following manner:

(1) In addition to the edge connector and the chassis ground, a circular path is placed around the entire periphery.

(2) Ensure that the annular width of all layers is greater than 2.5 mm.

(3) Connect the ring shape with a via hole every 13mm.

(4) Connect the ring ground to the common ground of the multilayer circuit.

(5) For double panels installed in metal chassis or shielding devices, the ring ground should be connected to the circuit publicly. The unshielded double-sided circuit should be connected annularly to the chassis ground, and no solder resist should be applied to the annular ground so that the annular discharge can act as a discharge rod for the ESD, and at least one position on the annular ground (all layers) A 0.5mm wide gap prevents the formation of a large loop. The distance between the signal wiring and the ring ground should not be less than 0.5mm.

Annular Ground Design In Circuit Board Reverse Engineering

In the area that can be directly hit by ESD, a ground line should be placed near each signal line. I/O circuits should be as close as possible to the corresponding connectors.

Circuits susceptible to ESD should be placed close to the center of the circuit so that other circuits can provide some shielding. Usually placed in series with resistors and beads on the receiving end, and for those cable drivers that are easily hit by ESD, consider placing resistors or beads in series on the drive end.

A transient protector is usually placed at the receiving end. Connect to the chassis ground with short, thick wires (less than 5 times the width, preferably less than 3 times the width). The signal and ground wires coming out of the connector should be connected directly to the transient protector before they can be connected to other parts of the circuit.